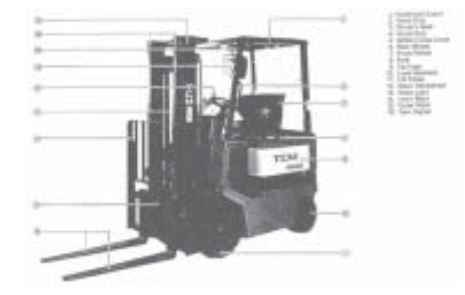

Forklift Trucks

General Safety Rules

Forklift Trucks are to be operated by experienced workers who are trained, certified or licensed as professional operators.

INSPECT forklift daily. Refer to page two of this training manual. Report all malfunctions to the designated authority. Do not operate unsafe forklift.

REPORT accidents/incidents promptly to your supervisor so they can be investigated immediately.

DO NOT PERMIT riders on any forklift.

ENSURE that battery retainers, fuel tanks and gas caps are secure before starting or moving forklift.

OBSERVE and obey the load capacity of the forklift.

SOUND the horn before moving the forklift when other vehicles or workers may not be able to see forklift movement.

PLACE forks as far under the load as possible. Drive with the load against the backrest with mast tilted back. Be sure that the forks are spaced correctly to support load.

DO NOT MOVE loads which are poorly piled or stacked.

CARRY the load as low as possible.

MATCH your speed to the surface being driven on, load and workplace conditions. Be careful when backing up.

TRAVEL in reverse when the load is blocking frontal vision.

INSTALL mirrors and/or stop signs at hazardous doorways, passageways and work areas.

MARK driving and work areas with yellow lines.

DO NOT DRIVE with arms, head or legs outside the confines of the forklift. Check operating clearance space.

WATCH for overhead obstructions at all times, especially when stacking or removing material.

DO NOT MAKE quick starts, jerky stops, or quick turns, particularly when stacking.

ALLOW three vehicle lengths between forklifts. (Tip of fork to forklift ahead)

SOUND horn and slow down when approaching pedestrians, doorways, cross aisles, ramps and other forklifts.

WATCH out for pedestrians. Avoid driving a forklift up to anyone who is standing in front of a bench or any other fixed object.

REDUCE speed when vision is restricted by doors, corners and elevations. Keep to the right unless plant or conditions or layout dictate otherwise.

DO NOT PASS a forklift travelling in the same direction at intersections, blind spots, or other dangerous locations.

DO NOT RUN over loose objects.

KNOW the forklift wheel position in relation to loading docks, trucks, box cars, and or platforms.

DO NOT HANDLE steering wheel if your hands or gloves are greasy or slippery.

PARK forklift with controls in neutral, parking brake on and forks in the lowered position. (Motor switch off.)

DO NOT ALLOW anyone to walk or stand under elevated forks.

DO NOT ELEVATE anyone on forks unless in approved man cage that is secured to forklift truck.

Forklift Trucks

Operator’s Daily Check

Make a daily visual and operational check.

WALK around the forklift completely, checking for obstructions.

INSPECT the general condition and cleanliness before getting on the forklift.

Visual pre-start up check.

FIRE extinguisher-present and charged.

LPG, GAS and DIESEL

engine oil level.

fuel level.

radiator water level.

ELECTRIC

electrolyte level.

battery plug connections

EVIDENCE of any damage: missing or loose bolts, nuts. guards, chains or hose heels.

WHEELS/TIRES condition.

FORKS positioning latched and carriage teeth in working condition.

CHAIN ANCHOR PINS worn, loose or bent.

FLUID LEAKS damp spots or drips.

LIGHTS head and warning. (If applicable)

HOSES held securely, not loose or rubbing.

BATTERY cables and water levels. (If Authorized)

As you walk around the forklift, check for:

OBJECTS on the floor that could cause an accident.

OVERHEAD obstructions.

NEARBY objects to avoid as you drive away.

Operational pre-use check.

Test operate all moving parts.

FOOT BRAKE pedal holds, unit stops smoothly.

PARKING BRAKE should hold against slight acceleration.

DEADMAN SEAT BRAKE should hold when operator rises from seat.

CLUTCH AND GEARSHIFT smooth shifting no jumping or jerking.

DASH CONTROL PANEL all lights, gauges and horn operational

STEERING smooth movement.

LIFT AND TILT mechanisms operate smoothly throughout cylinder stroke length.

LEAKS no external or internal leaks at lift and tilt cylinders. (Cylinders hold load). Also, no leaking hydraulic hoses.

Forklift Trucks

The Professional Operator

DO’s

OPERATE only forklifts that you are skilled licensed or authorized to operate.

KNOW the recommended load limit of the forklift and never exceed it.

KNOW how to assess the weight of load you are required to lift.

PERFORM a visual and operational check at the start of the shift.

KNOW that overloading the forklift can cause a lack of steering.

CHECK for adequate overhead clearance before rising the load.

OPERATE a forklift smoothly when stopping, starting, lifting and tilting

KEEP pedestrians away and raise and lower the load smoothly. Any elevated load is hazardous.

STAY in the truck in the event of an overturn.

KEEP hands, arms, head, feet and legs inside the confines of a moving forklift.

REPORT immediately any collisions, damage or near miss accidents to a supervisor.

STOP when a group of people is walking across the route being travelled: lower the load to the floor and wait until the route is clear, then proceed.

OPERATE in a congested area only as fast as conditions safely permit.

STAY constantly alert to changing or unusual conditions.

PREPARE for the unexpected and check:

-Hands, operators should wear gloves when moving or shifting loads or checking skids.

-Boots, operators should wear fully laced safety boots to give impact protection when moving loads or skids and laced to give necessary ankle support when mounting and dismounting forklift.

-Fork lift

-Load

-Route

WHENEVER anything develops that affects the normal operation of the forklift:

-Make a note of it on the pre use checklist

-Tell your supervisor immediately.

DO NOT’s

DO NOT TRY to move or adjust any part of the load, the forklift or the surroundings when on the forklift.

DO NOT LIFT a load that extends above the load backrest unless no part of the load can possibly slide back against the operator.

DO NOT ALLOW anyone but the operator to ride on the forklift.

DO NOT USE pallets elevated by forklifts as an improvised working platform.

DO NOT PERMIT anyone to stand or walk under the elevated part of any forklift, whether loaded or unloaded.

Forklift Trucks

Maintaining Control

INSERTING FORKS INTO PALLET

ENSURE the forks are:

-Level

-High enough to go into the pallet.

-As wide apart possible.

-All the way under the load.

LIFTING, TILTING, STACKING A LOAD.

LIFT the load straight up until it is clear, then tilt back.

WATCH that the load does not catch not catch on adjacent loads or obstructions.

DO NOT RAISE or lower the forks unless the forklift is stopped and braked.

ENSURE the forks are free of the load before you back up.

TRAVELLING

TILT the load backwards

TRAVEL with the forks 15-20cm from the floor and tilted back.

MATCH speed to driving conditions, load and workplace conditions

OBEY posted traffic signs..

DECREASED SPEED at all corners, sound horn and watch the swing of both the rear of the forklift and the load.

WATCH for pedestrians.

AVOID sudden stops.

DRIVING IN REVERSE

FACE to the rear

SOUND horn before moving

PROCEED slowly

STOP where vision is limited or blocked: sound the horn and proceed slowly

TRAVELLING UP OR DOWNHILL

KEEP the forks pointed downhill without load.

KEEP the forks pointed uphill with a load.

DO NOT TURN until you are on level ground.

DANGERS ON ROUTE

BE alert for the following dangers on the floor or roadway:

-Oil spots

-Wet spots

-Loose objects or holes

-Rough surfaces

-People

-Other vehicles

APPROACH at an angle when crossing railway tracks.

MAINTAIN a safe working limit from all overhead power lines.

PARKING

Every time you leave the forklift unattended, secure it.

PARK in an approved location.

SET the brakes.

LOWER the forks to the floor.

NEUTRALIZE the controls.

TURN off the motor switch.

DISCONNECT the battery or go through propane shut down procedures.

SAFE LOADS

DO NOT HANDLE unstable loads.