Forklift Trucks

Maintaining Stability

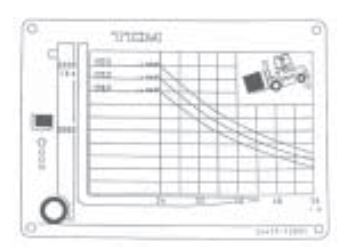

LOAD LIMIT

DO NOT EXCEED the recommended load limit of your forklift. Each forklift has a maximum load limit. The maximum load limit is shown on the data plate of the lift truck.

LOAD CENTRE

A forklift is designed on the principle of a teeter-totter.

POSITION load according the recommended load centre. The load limit of the forklift decreases as the load centre is increased.

DO NOT ADD extra weight to counterbalance an overload.

INSERT the forks all the way under the load.

KEEP the load close to the front wheels to keep the forklift stable.

CHECK for adequate overhead clearance before raising load.

ELEVATING THE LOAD

When the load is raised, the forklift is less stable.

When raising a load:

DO NOT RAISE or lower the foks unless the forklift is stopped and braked.

LIFT the load straight up or tilted slightly back.

DO NOT LIFT a load that extends above the load backrest unless no part of the load can possibly slide back toward the operator.

STEERING

The weight of the load is carried

by the front wheels: Turning is done by the rear wheels.

DO NOT TURN a forklift sharply at fast speeds.

DO NOT OVERLOAD a forklift. It can cause a loss of steering control.

DO NOT ADD extra weight to counterweight to improve steering.

MOVING A LOAD

KEEP the forks 15-20cm of the ground.

ENSURE vision is not blocked by the load.

DRIVE slowly.

AVOID sudden stops.

Forklift Trucks

Load Handling

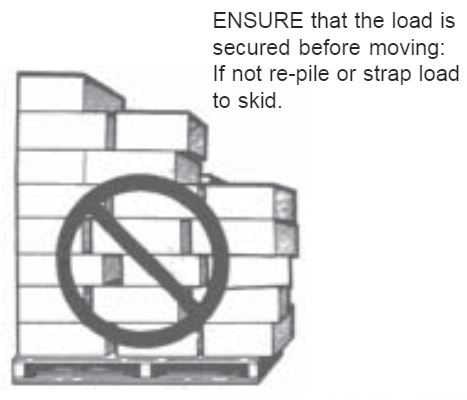

CHECK THE LOAD

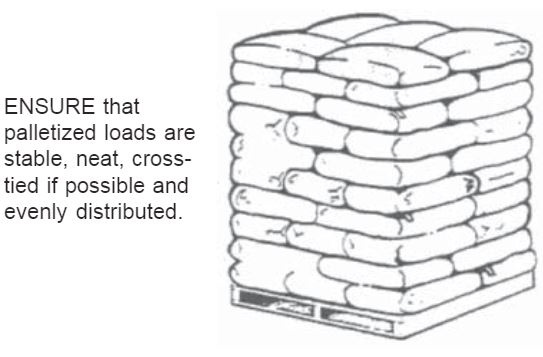

-Is it stacked correctly and securely?

-Is the pallet in good condition?

-Is the load within the recommended load limit of the forklift?

ENSURE that the mast of the forklift is in an upright position before inserting the forks into the pallet.

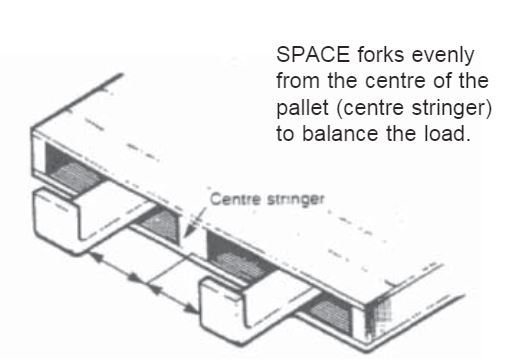

ENSURE that forks are adjusted for the most spread possible to fit the load.

SPACE forks as widely as possible to provide more even distribution of weight.

ENSURE forks are level before inserting them into the pallet.

ENSURE forks do not protrude past the back of the pallet when stacking in tight areas.

REMOVE damaged pallets from service.

CHECK the route you are going to travel before moving load. Look For:

-Overhead and doorway clearances.

-Dock plates secure.

-Weight capacity on floors and dock plates.

-Proper lighting.

-Floor in good condition.

-Obstructions.

Forklift Trucks

Loading and Unloading Vehicles

Vehicles include straight trucks, tractor trailers, railway cars and elevators.

ENSUE that the vehicle’s brakes are set and it’s wheels are properly chocked (blocked).

INSTALL fixed jacks to support a semi-tailer to prevent upending of trailer not couples to a tractor.

POST signs not to move vehicle.

CHECK that the height of the entrance door of the vehicle is adequate to clear forklift height by at least 5 centimeters.

CHECK the floors to see they will support the combined weight of the forklift and the load.

STAY clear of edges of docks, rail cars or ramps.

Edges should be clearly marked.

DO NOT TOW or push railway cars or trucks with a forklift.

DO NOT LEAVE forklifts running inside vehicle for long periods of time without ventilation.

INSPECT interior condition of vehicle:

-Trash, loose objects and obstructions.

-Check for holes or weak floors

-Ensure proper lightning.

-Check for overhead clearance.

DOCKS AND DOCK PLATES

ENSURE that dock plate is properly secured before driving over. Drive carefully and slowly over the plate. Do not spin wheels. Make sure that the plate will carry the load. (Load weight should be clearly marked).

INSTALL anti-slipping material in any area that could be a hazard because of weather conditions.

ENSURE that docks and dock plates are clear of obstructions and not oily or wet.

SET handbrakes, wheel blocks and detailer before entering railway car.

DO NOT PARK forklift within three metres of railway tracks.

DO NOT OPEN railway car doors with forklift forks.

ELEVATORS

DO NOT ENTER any elevator unless specifically authorized to do so. Before entering any elevator, ensure that the forklift plus the load weight does not exceed the elevator capacity. Approach the elevator slowly, stop at safe distance from the elevator gate and enter squarely.

NEUTRALIZE the forklift controls, shut off motor, and apply the brakes on the elevator.

Forklift Trucks

Batteries

SAFETY PRECAUTIONS

Batteries contain sulphuric acid and should be handled by trained and authorized personnel. They produce explosive mixtures of hydrogen and oxygen should be charged in approved battery charging areas.

INSTALL a safety shower and an eye wash in battery charging area.

WHEN HANDLING BATTERY ACID

WEAR splash proof goggles and protective clothing.

POUR the concentrated acid into water, not the water into acid. Use nonmetallic containers and funnels.

USE an eyewash station if electrolyte is splashed into the eyes. Force the eye open and flood with cool, clean water for about fifteen minutes.

USE extreme care to avoid spilling or splashing electrolyte (dilute sulfuric acid). It can destroy clothing and burn the eyes and skin.

NEUTRALIZE spilled or splashed electrolyte with baking soda solution, then rinse with clean water.

DO NOT STORE acid in hot locations or in direct sunlight.

DANGER OF EXPLODING BATTERIES

Batteries generate explosive gases.

KEEP sparks, flames, burning cigarettes, and other ignition sources away at all times.

SHIELD eyes when working near batteries.

Hydrogen and oxygen gases are produced during normal battery operation. These gases escape through the battery bents and may form an explosive atmosphere around the battery if ventilation is poor.

CHARGING BATTERIES

UNPLUG or turn the charger off before attaching or removing the clamp connections. Carefully attach the clamps to the battery in proper (red to positive and black to negative).

VENTILATE in the space where batteries are charged.

SERVICING BATTERIES

INSPECT for defective cables, loose connections, corrosion, cracked cases and covers, loose hold downs and deformed or loose terminal posts.

REPLACE worn or unserviceable parts.

TIGHTEN cable clamp nuts with the proper size wrench. Avoid subjecting terminals to excessive twisting forces.

USE cable puller to remove a cable clamp from the battery terminal.

REMOVE corrosion on the terminal posts, hold-down tray and hold-down parts.

USE a tapered brush to clean battery terminals and the cable clamps.

CLEAN dirt from the battery with a cloth wetted with a baking soda solution.

USE a battery carrier to lift a battery or place hands at opposite corners.

USE a self leveling filler which automatically fills the battery to a predetermined level. Battery cells should never be billed above the level indicator.

DO NOT SQUEEZE the syringe so hard that the water splashes acic from the cell opening.